Unique Product Questions 2025

These questions are very specific but have been asked in the past. These are specifically here as a resource for the AI to crawl to better help you.

Is there any place where we can order swatches?

While we do not currently offer swatches, a third party does seem to make options of our materials. This company is not related to Polymaker, but you can see some of their options for our materials HERE

Was PolyMax™ or PolyLite™ PC called either "PC-Plus" or "PC-Max" in the past?

This name change occurred quite a long time ago, but yes.

PolyMax™ PC was PC-Max PolyLite™ PC was PC-Plus

Do you have any suggestions for a wear resistant material similar to SLS igus' iglidur i3-PL-10000?

While we have not done testing or comparisons, CoPA or PA612-CF15 may be the best options to try.

Can you provide a US location and phone number for any SDS documents?

This is possible but may take us a few business days. Please reach out to [email protected] with the materials you need this for and we will work on creating them.

Previously made SDS documents with a US location: HT-PLA HT-PLA-GF PolyFlex TPU90 PolyFlex TPU95-HF Fiberon™ PETG-ESD

Do you have a UL certification for PC-FR? Can you make one?

I am sorry but PolyMax™ PC-FR (PC-FR) does not have a UL certificate (such as a UL Blue Card), but it has been tested for flame retardancy by SGS (included in the link I sent earlier) using the IEC 60695-11-10:2013/Cor.1:2014 Method B, which is equivalent to the UL 94 standard. The result achieved is V-0 classification, which is the highest rating for flame retardancy in the UL 94 test.

You can find our test results here: https://cdn.shopify.com/s/files/1/0548/7299/7945/files/PolyMax_PC-FR_Flame_Retardant_Report.PDF?v=1641463128

We do not currently have plans for UL certifications.

Is PETG safe around acetone?

The answer comes from the "CHEMICAL RESISTANCE DATA" section of the PolyLite™ PETG Technical Data Sheet. It states that the material has "Poor" resistance to strong acids, with a note explaining that "Poor" means the material becomes unstable upon contact with the chemical at ambient temperature. Acetone, a strong solvent, falls under this category. Thus, PolyLite™ PETG is not safe around acetone, as it will likely degrade or become unstable.

I have seen some people mention their hands get irritated when handling fiber filament printed items. Do you have any recommendations?

Ways to reduce irritation

Post-processing without exposing fibers

Minimize aggressive sanding that cuts into the fibers.

If sanding is necessary, finish with a very fine grit (e.g., 600+) to reduce sharp fiber tips.

Coating recommendations

Epoxy resin (thin layer) → Best for sealing fibers and adding durability.

Polyurethane clear coat (spray-on automotive type) → Easier to apply, good surface sealing.

Acrylic spray clear coat → Light-duty sealing, easiest method but less robust.

All these coatings will create a smooth surface that prevents fiber contact and can improve aesthetics and weather resistance.

Can you over dry CF-Nylon materials? Such as drying them when they are not wet?

Drying CF-Nylon when it's not wet won't hurt it, as long as you stick to the recommended temps and times. The real risk is overheating, not over-drying.

Is creep resistance on PET-CF significantly impacted by the lack of annealing?

There are several ways to improve creep performance:

1. Increase the wall thickness and fill density of the printed part to ensure that the printed surface under stress is printed in the plane direction rather than the Z direction.

2. We strongly recommend annealing, which will effectively improve creep. If annealing is not possible, we recommend setting the load-bearing surface as the printed bottom surface.

3. If deformation cannot be suppressed, we suggest adding a spacer to reduce some of the pressure.

Is it safe to cut PLA with a CO2 laser? Does your material contain any PVC or other materials that should not be cut with a CO2 laser?

Our PLA contains no PVC but it does off gas pretty dramatically. So unless someone has a VERY good ventilation setup, it’s going to be too toxic of an environment.

Long story short, it will cut ok with a CO2 laser, but we wouldn’t suggest it.

My Anycubic ACE Pro is giving filament tangling issues with your Matte PLA, why is this?

This is an issue specific to the ACE Pro setup and specific to Panchroma Matte PLA. We are not sure why this happens and we are investigating this internally. But again, this is specific only to the ACE Pro and Panchroma Matte PLA.

If you do a lot of drying cycles of a CF-Nylon, does the performance of the material degrade?

Repeated drying of CF-Nylons at the right temps shouldn't make it brittle or degrade it. Just make sure to not dry at above the recommended temperature.

Does any carbon fiber nylon material Polymaker produces contain PFAS?

There is no PFAS in any PA-CF formula.

Can I use automotive spot putty thinned with Acetone on Fiberon blends without compromising strength, warpage and temperature resistance?

Use of Automotive Spot Putty (Thinned with Acetone)

Spot putty can generally be used on nylon composites like PA6-GF25 and PA6-CF20, but there are a few key points to consider:

Acetone is not recommended for nylon-based materials. Nylon is partially sensitive to polar solvents like acetone, which can cause surface softening, swelling, or internal stress—especially on semi-crystalline polymers like PA6. This may lead to localized strength loss or stress cracking over time.

Instead, we recommend using epoxy-based or polyester-based fillers without strong solvent thinning, or using a plastic-compatible spot filler designed for automotive bumpers or nylon-based plastics.

Always test any filler or putty on a small section of the part before full application.

Polyester Resin Coating – Risk of Warpage

Your concern about heat from resin curing is absolutely valid:

Many polyester resins are exothermic during curing, with internal temperatures potentially exceeding 80–100°C, depending on volume and ambient conditions.

Since PA6 composites begin to soften above ~100–120°C (though not deforming severely until ~200°C), thin-walled or lightly supported parts could warp during curing, especially if clamped or unevenly supported.

If you want to use a coating approach, here are a few safer options:

Recommended Finishing Options

2K Epoxy Primer or Automotive Filler Primer

These primers offer good adhesion to PA materials (especially with mild sanding or adhesion promoters) and are thermally stable during curing.

Automotive Plastic Adhesion Promoters

Use an adhesion promoter formulated for PA or PP surfaces before applying topcoats or fillers.

Low-exotherm Epoxy Resin Coating

If you want a resin coating, choose a low-exotherm epoxy system designed for composite surface smoothing. Test on a small part first to ensure dimensional stability.

Mechanical Finishing + Paint

For the cleanest result: sand, apply filler primer, re-sand, and finish with automotive paint system designed for plastic body parts.

Summary

Avoid acetone-based spot putty directly on nylon parts

Polyester resin could cause warpage—use with caution or avoid for large/thin parts

Use plastic-compatible fillers, low-exotherm coatings, or primer-filler + paint stack as a safer approach

Do you have materials with biocompatibility?

At this time we do not have a material that has passed the rigorous testing for biocompatibility, but we are working on this.

Why do the PLA products carry a proposition 65 warning for benzene?

This was a judgement from the Product Team. The hypothesis was benzene is a common used ingredient, CA-65 require manufacturer to list at least one material, but we could not test all of our products so the product team decided to list Benzene on the sticker. It doesn't mean our products carry benzene.

We may do further testing in the future to see if we can remove this label.

What is the moisture content of Fiberon™ materials at the time of packaging?

All Fiberon™ filaments are dried and vacuum-sealed to ensure a moisture content of less than 0.3%. Based on our batch-level tests, typical results fall under 0.15%.

Do you dry Fiberon™ filament after water cooling during extrusion?

Yes. All Fiberon™ filaments undergo a dedicated post-extrusion drying process before winding and packaging.

Why does printing ESD materials at higher temperatures drastically reduce resistance?

Higher print temperatures improve the mobility and dispersion of CNTs (carbon nanotubes) in the polymer melt, allowing better network formation. This enhanced connectivity reduces surface resistance, sometimes by multiple orders of magnitude.

Do you have EN71-3 testing for the EU for toys for any products?

As of right now we do not. But this is something we are currently looking into.

What Polymaker filament offers resistance to common paint thinners/solvents?

PPS would be the best option for this, so we would suggest either Fiberon™ PPS-CF10 or Fiberon™ PPS-GF20.

How does the poly dryer work and how come it is the same fan and heater making 3 different power levels?

The adjustment of settings and temperature is mainly achieved through current regulation. The fan speed (RPM) and air volume flowrate are fixed and do not change to adjust the settings. Similarly, the heater power remains constant; however, the overall power consumption varies depending on the target temperature and changes in air temperature, which is mainly caused by current regulation.

Please find below the relevant specifications of the fan.

What material would you suggest that is small like this and creep resistant?

The best option for this would likely be PolyMax™ PC.

Do you have any information about the dissipation factor of the PPS-GF20 material?

We have not tested dissipation factor before.

We've done some checking and we do have small doses of other components in our formulations for improving the printability of the material, and these may cause an elevated dissipation factor, but we don't have specific values to provide. It is recommended that corresponding tests be performed under the parameters of the specific application.

Also we understand that the high crystallinity of PPS helps to reduce the dissipation and dielectric constant, and it is recommended to anneal the material at 130 degrees or 230 degrees before testing.

Also, there are values for dielectric constant in TDS that may help.

I'm planning to use PolyCast filament not for lost-wax casting, but for lost-foam casting — is this possible?

No it wont work, the molten metal is not enough to get rid of the PolyCast pattern.

The foam is easy to burnout and vaporize in contact of molten metal, we think PolyCast is too dense.

Can HT-PLA be used as support material for higher temperature materials?

Yes! HT-PLA has been tested by the community and it does work as great support material for PET-CF. It may work for other high temperature materials as well, but so far only PET-CF has been tested.

Do you have relative permittivity for ABS and ASA?

We are sorry but this is not something we have at this time.

Can you sell empty spools?

I am sorry but we do not offer to sell empty spools at this time. It may be worth checking with our very active Discord community though to see if any members have empty spools they can give away.

There seems to be a line above the plunger seal on my PolyDryer box. Is this normal?

Yes this is normal. That's the injection molding seam.

It is hard to remove entirely especially with transparent material

Does PPS-CF or any other materials require ventilation while annealing?

While good ventilation is required for all materials while printing, annealing should not as the temperature does not go high enough to justify requiring ventilation.

Are your 5KG plastic spools recyclable?

Our 5KG spools are made of PP (polypropylene) and even include some recycled PP. It is recyclable so long as you check with your local recycling facility first.

Does ASA printing produce VOCs?

Yes, normally the smell during ASA printing is stronger than PLA/PETG, because there is more small molecules remained in ASA from polymerization process, which could be thought as the inherent property of ASAWe also recommend checking out this video by Thomas Sanladerer: https://www.youtube.com/watch?v=nofn_MHrxrsAs you can see in that video though - it is recommended to have proper ventilation and filtration regardless of the plastic you are printing with.

Do you have a certificate that TPU90 complies with the essential safety and performance requirements of Regulation (EU) 2017/745 of the European Parliament and of the Council of 5 April 2017 on medical devices?

The tests done on PolyFlex TPU90 are by method of ISO 10993 - 5(Tests for in vitro cytotoxicity), 10(Tests for irritation and skin sensitization), 11(Tests for systemic toxicity), 23(Tests for irritation)All the test reports are attached. Here are some learnings

the iso 10993 is the standard for medical devices (not for material). (EU) 2017/745 is also the standard for medical devices (not for material). In terms of this case, the tests should be finally done on printed insoles which means materials, printers, process of printing, environment of printing, etc are all related with the final result. and the tests should be done by our customer, if their products are regarded as the medical devices which need to follow (EU) 2017/745

The purpose of material companies (like us) to do the test on material is only to enhance the confidence that the final products(like insoles) can pass the test

In general understanding, material can pass ISO-10993 -5/10/11/23 is good for skin contact application

What are the shrinkage rates for our nylons? How much does CoPA or PA6-CF or PA12-CF or PA612-CF or any nylon shrink?

This depends a bit on if you are talking about the part right after it is done printing and annealing, or if you mean after you allow it to get moisture conditioned. Right when you are done annealing the nylon print, it will shrink slightly, but after leaving it out to be moisture conditioned, the part will actually grow a bit as it absorbs moisture.

More data can be found HERE

How do I combine two PolyCast or PolySmooth PVB prints together?

To combine two PolyCast parts: Alcohol (it is a good solvent for PVB, which is dissolved into liquid then bonded through two halves, and then the solvent evaporates into a solid)

What coating or plaster is best to pair with PolyCast for investment casting?

For investment casting with PolyCast filament, the choice of ceramic coating can depend on the type of metal being cast and the desired surface finish. Common options include:

Silica-Based Coatings: Widely used and generally compatible with various metals.

Zircon-Based Coatings: Often preferred for high-temperature applications as they provide better thermal shock resistance.

How Hygroscopic is your Fiberon PPS-CF? How affected by moisture is it? Does PPS-CF require a filament dryer?

PPS-CF has a very slow moisture absorption rate and is not sensitive to moisture. However, moisture adhering to the filament can degrade the appearance of the printed parts. Therefore, we recommend using a PolyBox or PolyDryer to store the filament. If the filament has been exposed to the environment for more than 3 days, we suggest drying it again before use.

Can I print Fiberon PPS-CF at 300 degrees Celsius? Can PPS-CF be printed at a lower temperature?

We’ve set the minimum recommended printing temperature for PPS-CF at 310°C because, although extrusion is possible at 300°C, it can lead to significantly reduced interlayer bonding strength. This would negatively impact the overall performance and user experience.

Will we get Fiberon spools in 1KG? PET-CF, PPS-CF, PA-CF. 1KG spools for Fiberon?

We will not be making any Fiberon 1KG spools in the near future due to the fact that carbon fiber blends are more brittle on the spool and difficult to wind tightly. This means the core on the spool is larger and 1KG of filament will not fit on a 1KG spool.

We do offer 3KG options though for all Fiberon products.

What is PPS-CF10's chemical compatibility in contact with crude oil and aromatic solvents at ~120C for extended periods of time (several months)?

We have optimized the printability of PPS-CF10, making it easier to work with, but the base material remains PPS. PPS inherently possesses good resistance to oil and aromatic hydrocarbons, and we believe these chemical resistance properties will remain unchanged in this blend.

However, due to the specific nature of your application, we recommend conducting some testing to validate the material’s performance before full implementation. This will help ensure that any potential differences arising from switching materials do not adversely affect your results.

Is there a way to seal Carbon Fiber Nylon? This includes PA6-CF PA12-CF PA612-CF. Is there a way to make carbon fiber nylon water tight?

We didn't do rich experience on this, but we found there are several articles on the make parts water tight by using proper printing process.https://all3dp.com/2/watertight-3d-print-tutorial/https://blog.prusa3d.com/watertight-3d-printing-pt1-vases-cups-and-other-open-models_48949/

Is there a UL94 certification for PPS-CF? Is PPS-CF UL94 certified?

There is no UL94 certification for PPS-CF

How does PETG-ESD surface resistivity vs printing temperature work? Does printing temperature affect surface resistivity?

The surface resistivity is related with the nozzle temperature, as the surface resistivity related with

the conductivity of material

the adhesion of shell to shell and layer to layer - less space within the shell to shell and layer to layer help to lower surface resistivity

Therefore using higher nozzle temperature helps lower the surface resistivity.

More info HERE

Whys is the glass transition temperature (Tg) lower than the Heat Deflection Temperature (HDT) for Nylon Materials (or any other material that this is true for)?

The glass transition temperature (Tg) refers to the temperature at which the amorphous regions of the polymer soften. However, HDT is a measure of the material’s ability to bear loads at elevated temperatures, which is more influenced by the crystalline regions and fiber reinforcement. Since the crystallinity increases during annealing, the HDT can surpass Tg as the material remains structurally stable at higher temperatures under load.

Annealing encourages increased crystallinity in the polymer. For PACF, this means the crystalline regions within the material become more organized and dense. These crystalline regions have a higher thermal stability than the amorphous regions, allowing the material to maintain its shape and stiffness at higher temperatures, even above its Tg.

Are the CF Fibers in various filled filaments the same across blends (PA6, PA12, PA612, etc) with only differing amounts of fiber? Or are the fiber lengths themselves different as well?

For PA6-CF, PA12CF and PA612CF, we are using same carbon fiber in production. For PET-CF, the carbon fiber will be shorter because the different process. For PETG-rCF, the Fiber is different and comes from recycled material.

Is PET-CF Chemically Resistant?

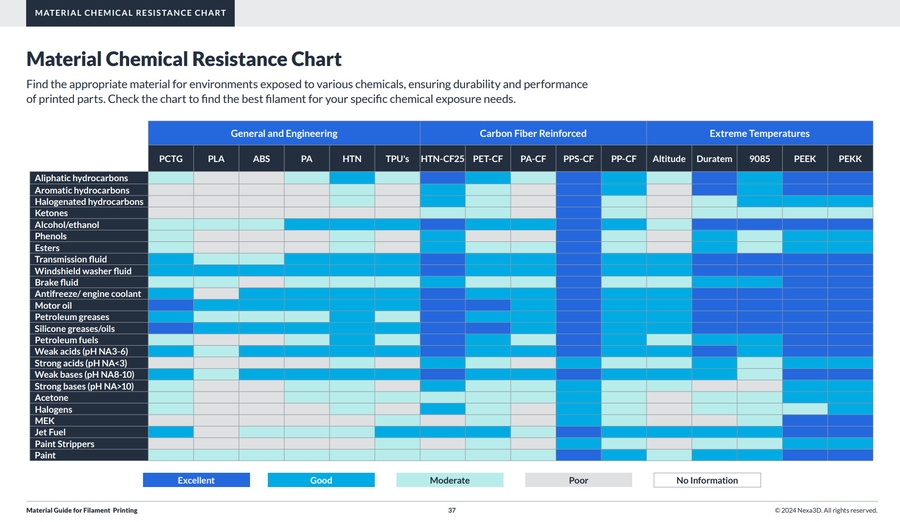

The chemical resistance is mainly decided by base material, and PET generally has a good chemical resistance. Check the charts below:

How do our Glow in the Dark Filaments Glow? Does our Glow in the Dark filaments use Zinc or Strontium Aluminate?

In terms of our Panchroma Glow, there is strontium inside but no zinc. For further information, the total noctilucent powder content in filament is 2-2.5 wt%, but we don't know the exactly strontium element content inside.

How are hex codes determined?

Hex code is currently an estimation of the perceived color: we take picture of a same print under the same lighting condition and run each pixel through an algorithm which output the HEX code

How are TD (Transmission Distances) determined?

The TD is measured with the TD-1 on the reference batch

Do any of our filaments have bisphenol a in them? Do any filaments have BPA? Does a certain material use BPA?

Bisphenol A is commonly used to polymerize into PC materials.Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA). But no other product should.

Does any of our filament pass PLA EN 13432 conditions?

As we didn't go deep into this application (packaging), none of our product has been tested by this standard so far.

What is the difference between Panchroma Satin and Panchroma Matte?

Really it is just the finish - Panchroma Satin being less Matte than Panchroma Matte. But when it comes to branding our Panchroma Satin was our PolyTerra PLA + rebranded as Panchroma Satin. So Satin is slightly stronger than Matte - but didn't find it was strong enough to justify the "+" Label - so we are just calling it off the surface finish now

What are the specs of the fan used for PolyDryer, including rpm and air pressure?

The fan speed (RPM) and air volume flowrate are fixed and do not change to adjust the settings. Similarly, the heater power remains constant; however, the overall power consumption varies depending on the target temperature and changes in air temperature, which is mainly caused by current regulation.

Is Panchroma Translucent Natural PLA the same product as PolyLite PLA Natural?

Yes - they are the same product - just under new branding

Does the PolyDryer power supply have a safety listing from Intertek or UL?

Yes! Find those here: UL Test Report GCC Certificate

Can I turn the beep off on the PolyDryer?

This is not something that can be changed - though new units produced after May 2025 can: In the “SETTING” mode, press and hold both the “Pause” and “Decrease” buttons for 5 seconds to enter the buzzer level setting mode. The display will show “bu-01”. Use the “Increase +” or “Decrease −” buttons to adjust the volume. There are 3 volume levels available. After setting the desired volume, press the “Pause” button to save the setting and exit back to the “SETTING” mode.

Will TPU be able to handle as cold as -25℃?

TPU is not recommended for these cold temperatures as it is below the glass transition temperature - making the TPU more hard and brittle.

Is there a way to use the PolyDryer with the PolyBox?

There is a downloadable file you can use here: https://makerworld.com/en/models/1418219-polybox-ii-polydryer-remix?from=search#profileId-1473071

Do you have any data on the compressive strength of ASA or ABS?

We do not have this data at this time.

Is there a way to recharge the UV transition PLA?

The effect will last just a couple of passes unless putting the print under UV for a long time.

Nylon's properties change dramatically depending on if they are printed wet or dry, however, it does not seem to effect the heat deflection temperatures of the material based on your spec sheets. Is this true?

HDT is primarily a function of the polymer's crystalline structure and glass transition temperature, which are not significantly affected by absorbed moisture.

While moisture reduces tensile strength and modulus, the softening point under a given load (which HDT measures) remains relatively stable because it depends on the thermal transition of the base polymer and fiber reinforcement, not on small changes in the amorphous regions.

That being said, long-term thermal aging in humid environments can still accelerate degradation of properties, even if HDT under short-term testing remains similar.

So in short:

Although the HDT of PA6-CF is largely unaffected by wet vs. dry state, this does not mean performance under heat and load will be identical in real-world conditions, because creep resistance and dimensional stability may still decline with moisture.

If your application involves continuous exposure to high temperature and humidity, we recommend:

✔ Printing with dry filament

✔ Annealing after printing to improve crystallinity and dimensional stability

✔ Considering PET-CF or PPS-CF for superior hydrolytic stability if moisture resistance is critical

What are the HS Codes for your products?

HS code Filament: 3916909000

HS code Polybox: 84193900

HS Code PolyDryer 8419390000

HS Code PolyDryer box 8419908590

HS code Polysher: 8465930000

HS code Nebulizer: 8424300000

HS code pellet PolyCore: 3903900000

Is there a way to recharge the UV transition Panchroma PLA as the UV change has degraded over time?

Once the UV transition effect in the PLA fades, it can't be recharged or restored—this is a known limitation of the material.

Does the temperature resistance of a nylon change when wet vs when dry?

Nylon-based materials, including PA6-CF, show significant mechanical property changes depending on moisture content. Strength, stiffness, and dimensional stability typically decrease as moisture absorption increases.

However, regarding Heat Deflection Temperature (HDT):

HDT is primarily a function of the polymer's crystalline structure and glass transition temperature, which are not significantly affected by absorbed moisture.

While moisture reduces tensile strength and modulus, the softening point under a given load (which HDT measures) remains relatively stable because it depends on the thermal transition of the base polymer and fiber reinforcement, not on small changes in the amorphous regions.

Fiberon spools are wearing out my hardened nozzle - is this to be expected?

Nozzles are consumable parts and all carbon fiber materials are going to wear out the nozzles. And the harder the fiber and the higher the content the faster it will wear out. The hardened steel nozzle material slows this process down. If there is a high demand for model accuracy, we recommend changing the nozzles regularly for printing.

Also nozzle wear is not linear, so if you don't want to change nozzles frequently, consider using 0.6mm nozzles or adding a dimensional compensation after a period of time to keep things stable.

What is the HS Code for Polymaker products?

HS codes are the same per product form:

HS code Filament: 3916909000

HS code Polybox: 84193900

HS Code Polydryer 8419390000

HS Code Polydryer box 8419908590

HS code Polysher: 8465930000

HS code Nebulizer: 8424300000

HS code pellet PolyCore: 3903900000

Do you have any info on heat creep with Polymaker CoPE?

If heat creep means filament becomes soft in the cold end and resultsi in clogging. Then, CoPE performs similarly to regular PLA (without jam-free) because of similar thermal properties.

Is it possible to use the traditional plaster method for casting a printed PolyCast filament model?

We dont really recommend plaster casting cuz it is usually not strong enough, you would need a very long burning process.

Here is a guy that tried casting with plaster: https://www.youtube.com/watch?v=QeNMc_THrow

Do you have thermal conductivity info for Polymaker products?

We do not have this information as polymers are not normally used for their thermal conductivity.

Do you have CTI values for your products?

No, we suggest to take reference of base material. 3D printing parts has different infill, will change the total parts' property

Is your PETG-ESD range suitable for an ATEX zone?

Our Fiberon™ PETG-ESD is formulated to provide stable electrostatic discharge (ESD) properties, but please note the following important points:

The material has been tested internally for surface resistance values that fall within the ESD-safe range.

However, it does not carry third-party ATEX certification, nor has it been validated specifically for explosive atmospheres.

Because 3D printing parameters, part geometry, and environmental conditions (such as humidity and wear) can all influence ESD behavior, we cannot guarantee compliance with ATEX requirements based solely on filament data.

At this time, we do not offer filaments with formal ATEX approval. If your application requires certified materials, we recommend conducting application-specific testing under your operating conditions or pursuing certification with a notified body using printed parts.

That said, if your requirement is primarily to maintain consistent ESD performance, we suggest:

Printing PETG-ESD at higher nozzle temperatures (around 270 °C) to achieve optimal conductivity.

Regularly testing the surface resistance of printed parts to confirm they remain within your required range.

Why are the tops and bottoms of my print less shiny and more matte than the shell walls?

This is caused by how FDM printers lay down layers, which scatters light and makes the surface less glossy. Sides look clearer because of the way the layers stack. You can try lowering fan speed, slowing down print speed, or tweaking temperature, but some matte finish is just part of the process.

Are you discontinuing your 2.85mm filament?

Yes - this is slowly being discontinued due to lack of demand. We still have the ability to make custom spools though of any size, though we have a large 1,000KG minimum order for something like that.

What happened to your PolyMax PC-FR?

We had some raw material sourcing issues and it is currently not being produced. We are investigating an alternative solution at this time.

In the meantime we suggest checking out either PPS-CF or PPS-GF as they are both V0 flame retardant.

Do you have suggestions for print settings (Z-gap and support interface density etc) for using Pachroma CoPE as support material for PLA?

The suggested support settings when using support for PLA would be used - such as a 0mm Z distance.

Does Fiberon™ PETG-ESD (Formerly PolyMax™ PETG-ESD) filament meet ANSI S20.20 ESD Standard

Fiberon™ PETG-ESD (formerly PolyMax™ PETG-ESD) has been internally tested to demonstrate stable surface resistance within the ESD-safe range. However, the material itself is not formally certified to ANSI/ESD S20.20 or other third-party standards at this time.

Because 3D printing introduces variability (printer settings, geometry, environment, etc.), the ESD performance of finished parts can differ. For this reason, we recommend that customers validate the ESD properties of their specific printed parts under their required test standards.

Does Fiberon PET-CF17 stick to standard PETG in a single print?

Fiberon™ PET-CF17 and standard PETG are generally compatible and can adhere to one another during printing, since both are PET-based materials. This makes it possible to use PET-CF17 as a structural core with PETG as the outer layer.

That said, we recommend carrying out application-specific testing before using this combination in final parts. While adhesion is usually good, a few considerations are important:

Mechanical differences: PET-CF17 is reinforced and has higher stiffness with lower shrinkage, while plain PETG is more ductile. This mismatch may cause internal stress, particularly in large bonding areas or under thermal cycling.

Practical advice: For smaller surface interfaces, the materials typically bond well. For larger contact areas, we do not recommend relying solely on adhesion, as stresses may accumulate and affect long-term stability.

Process conditions: Drying both filaments and printing at sufficiently high nozzle temperatures will help ensure good interlayer fusion.

In summary, the combination can work, but please validate it with your application requirements. For demanding mechanical parts, we recommend avoiding very large bonding areas between PETG and PET-CF17.

Do you have any skin safe data for our Panchroma Matte or other Panchroma PLA products?

No, we don't have any skin safe data for Panchroma. The biggest challenge on this is that there is no industrial standard on food/skin safety filaments.

Do you have compressive strength data for PET-CF?

Sorry, we do not publish a single, generic “compressive strength for annealed PET-CF17 through-bolted connections” because the compressive/bearing performance of FFF parts depends strongly on print orientation, wall thickness, infill, annealing procedure and local geometry.

Do you have a declaration that your filaments are PFAS/PFOS free?

Yes you can find that in our Certifications and Declarationspage.

What ESD testing methods were used on your Fiberon ESD materials?

The surface resistivity for Fiberon™ PETG-ESD and PA612-ESD is tested using the ANSI/ESD STM11.11 standard on 3D printed bars

My PETG-rCF prints are sticking to well to the build plate.

We can recommend to use PVA/PVP glue to help

The tape at the end of a Fiberon spool is causing my prints to fail - can this be fixed?

Yes! This has already been fixed for any Fiberon products manufactured after August 2025.

Do you have a General Certificate of Conformity(GCC) or Children's Product Certificate(CPC) for your filament?

You can find our GCC on our Certifications and Declarationspage

Do you have dielectric constant data for PETG-ESD?

No, dielectric constant is more for insulation material such as Fiberon PPS-GF20, which we do have this data for.

Do ASA-CF or Panchroma Luminous require a 0.6mm nozzle or are they good to use a 0.4?

All Fiberon filaments are good with 0.4mm. Panchroma Luminous doesn't require 0.6mm nozzle but needs a hardened nozzle.

What temperature should I use on a soldering iron to put in a heat set into filament?

There is no perfect number but we would suggest right around or slightly above the extrusion temperature. You will have to act fast at this temperature so you can reduce the temperature if that is too high.

Is the red flashing light on my Polydryer implying it is malfunctioning?

No! The red flashing light means it is working and actively drying.

Noticing ASA supports are causing uglier prints with same settings as ABS - what do you suggest?

Some individuals have found better results with support material on ASA by decreasing the support Z-gap vs ABS.

Do you have a recommended support material for PET-GF?

It is compatible with polysupport for PA12 or PLA. However, based on R&D tests, the adhesion is too strong to be considered supportive. Therefore, we did not include it in the TDS.

Right now we do not have a material we suggest.

Is there a measurement to determine creep?

There is - but it can be very costly. We are developing our own in-house method to measure creep and should be added to TDS documents in the coming future - but no ETA at this time.

Why is there a discrepancy between your TDS and App for Young's Modulus in the Z-axis for PolySmooth?

They are both correct but different testing methods, the Material App is the newest testing method.

Old Testing Method: Printing a dog bone vertically

New Testing Method: Printing a cylinder and die cut the dog bone shape from it

TDS will be updated shortly.

Does your polylite PC PC01001 contains silicone or silicone-based components?

No, it does not contain Silicone or silicone-based components.

PET-GF is sticking too well to my textured PEI, any suggestions?

This is most noticable with clean, new textured PEI plates. We suggest using some glue stick on your build plate and waiting until the build plate is at room temperature before trying to remove the part.

Do you have a white easier to print version of your Fiberon TDS?

Not at this time but we will be launching a new version of our app shortly where you will be able to export TDS information into a printable PDF.

Why can't I buy PC-FR?

We have sourcing issues for raw materials and so we are not currently manufacuturing this.

Do you have the thermal conductivity (λ) or U-value data of PolyLite™ PLA?

The thermal conductivity of PolyLite PLA in the solid state can be referred to: 0.231W/(m*)K, and the very detailed data is not available for the time being.

In addition, the thermal conductivity data is not a fixed value, which is related to the crystallization state, melting state and other condensed states of PLA materials.

Do you know any foundries that can use your Polycast in Europe?

We have been in contact with this French company before:

Here's one we know of in the Netherlands, that has worked with our Polycast before:

https://www.kustersgoumans.nl/nl/

Here's a very big company that has locations across Europe that I found through Google:

Do you have a tough/abrasive resistant PTFE tube you can suggest for abrasive filaments

We do not know of any - we are sorry

Do you offer DMA (dynamic mechanical analysis)?

There are many type of DMA - we do not have this data but please let us know what you need and we can look into it

Do you have plans to include formulation codes to products - so that there is the same code regardless of the spool size or filament diameter being used?

We do not have plans for this at this time

Can you please tell what actually Matte makes different from "normal" PLA? It says "with organic/mineral filling". What exactly does that mean?

Organic filler derives from living or once-living organisms like plants. Starch is a good example which is the raw material for PLA.

Mineral fillers derived from naturally occurring rocks and minerals that are mined and ground into a fine powder. Clay and Silica are typical examples here.

Panchroma™ Matte PLA formula has a higher compostability than regular PLA because it has a different formula.

But I am sorry that we can't communicate what exact material that we use in Panchroma Matte PLA, because it is confidential information to our material formula.

Can you use any PolyFlex TPU in the AMS?

At this time (12/5/2025) there are no TPUs we offer that are compatible with the AMS

Why is my filament fused together on the spool?

This is normally because the spool was heated up too hot for the material. Be careful to always dry your filament at the recommended temperature range to prevent this.

We noticed that PETG-ESD is having different surface resistance depending on the section on the print - why is this?

Why the bottom surface is more conductive

For PETG-ESD, the ESD performance comes from the conductive pathway formed by carbon nanotubes (CNT).

The bottom surface, pressed directly against the build plate, has strong melt compression and excellent CNT alignment, resulting in lower resistance.

The top surface, especially if the melt flow is not fully merged or is cooled too quickly, can form weaker CNT contact, which leads to extremely high resistance values.

This difference can become very large if the top layers are not dense enough or if the melt does not fully coalesce.

How to improve top-surface ESD performance

To significantly reduce resistance on the top surface, we strongly recommend:

Increase top layers to at least 6–8 to ensure full melt merging.

Use a solid top infill pattern (rectilinear or concentric).

Lower top-surface print speed (20–40 mm/s) to improve melt fusion.

Increase flow to 100–105% for the top layers.

Perform top-surface ironing, which can greatly improve CNT connectivity by re-melting the surface and allowing the CNT network to reform more uniformly.

Ironing is often the single most impactful step when users see extremely high resistance on the top layer.

Are there toxic fumes or vapors when PolyCast is burned or melted?

The glass transition temperature of components in Polycast is 60–70 °C, so temperatures above 335 ℉ may cause small amounts of components to leach out.

Additionally, the “sweet” smell generated during Polycast heating needs to be further confirmed. Identifying the specific compound responsible for the “sweet” smell would require outsourcing for testing, which could take a considerable amount of time.

As a short-term solution, we suggest the customer reduce the temperature used during the wax burnout process.

What is the darker brown in the Panchroma dual gradient wood PLA, do you sell it on it's own?

It is Earth Brown Matte PLA - but it won't look identical from what is is mixed in the gradient colors. Simply because, gradient color production process is mixing colors together all the time.

What support material would you suggest for PolyCast?

PolyDissolve works best. You can also use PLA as a breakaway support material option.

What is the support material you would suggest for Fiberon ASA-CF08?

We recommend PolySupport for PA12, as it is specifically designed for support material. PLA can be considered as an alternative.

Do you have any options to purchase a replacement spool roller for the PolyDryer?

Not for now. So we would suggest to print one. Here's the reference data: length 90.5mm, Φ20.8mm.

Do you have an adhesive recommendation for a build plate for Fiberon PETG-rCF?

We have not done tests but we assume that 3D Gloop for PET should work.

Is it possible for us to please receive SDS sheets that list 100% of the composition?

We are sorry but we cannot release that information as it is proprietary

Do you have HDT data for PPS-GF NOT annealed?

There is a common misconception regarding the provision of unannealed HDT for crystalline materials. For PET-GF15, we provide the HDT of the material 'as printed' state. However, this only represents the HDT of printed samples and does not apply to the unannealed HDT across all printing processes. This is because different printing processes result in varying initial crystallinity levels, which significantly influence the HDT of crystalline materials.

To assess the minimum heat resistance of materials in an unannealed state, I recommend using the glass transition temperature (Tg) as a reliable reference point. Additionally, our tests show that the PPSCF formulation has minimal differences compared to Bambu. Our mechanical properties are slightly lower than Bambu's, but our printing performance is somewhat superior.

Do you have butadiene content for your ABS?

We are sorry but we do not have this information to share

Will your PPS-GF work for an application with a line voltage of 230V?

Electrical insulation perspective

PPS (polyphenylene sulfide) is intrinsically a good electrical insulator, and the addition of glass fiber (GF) does not make the material electrically conductive. From a bulk material standpoint, PPS-GF maintains high volume resistivity and dielectric strength, which are suitable for typical low-voltage electrical insulation applications, including 230 V systems.

However, for 3D-printed parts, electrical performance is influenced not only by the base polymer but also by:

Layer-to-layer interfaces

Internal porosity

Print orientation and wall thickness

Environmental factors such as humidity and contamination

Because of this, printed PPS-GF parts should be treated as structural or functional insulation, not as a certified electrical safety barrier unless validated.

Safety and compliance considerations

We do not claim third-party electrical certification (e.g., IEC, UL insulation class) for 3D-printed PPS-GF parts.

If the part is used in proximity to live conductors, creepage and clearance distances must be designed according to the applicable electrical standard, independent of the material choice.

For critical applications, dielectric withstand and insulation resistance testing on the final printed part is strongly recommended.

Thermal and environmental suitability

PPS-GF is particularly well suited if the application also involves:

Elevated operating temperatures

Thermal cycling

Exposure to oils, fuels, or aggressive chemicals

These are areas where PPS-GF typically outperforms many engineering plastics.

Practical recommendations

To maximize electrical safety in a 230 V application:

Use multiple perimeters and high infill to reduce internal voids.

Avoid thin sections near live conductors.

Ensure the part remains dry and clean during service.

Validate the printed component under actual operating conditions, including voltage, temperature, and humidity.

Summary

Material capability: PPS-GF itself is suitable for 230 V from an insulation standpoint

Key limitation: Final electrical safety depends on part design and print quality

Best practice: Perform application-specific electrical testing before deployment

Last updated

Was this helpful?