Oozing

In this part we will differentiate two kind of oozing depending on the root cause.

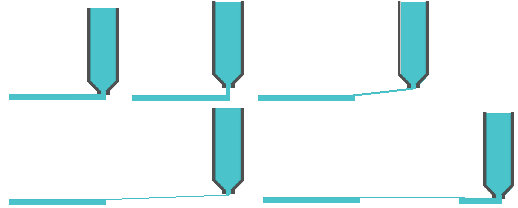

The first root cause is oozing created by the extruded filament being linked with the material inside the nozzle. The extruded filament will then force the material inside the nozzle to stretch out of the nozzle as the nozzle is moving to another location. We will rename this phenomenon as stringing (because of this string created).

Polymers with a high molecular interaction, or polymers which have absorbed moisture tend to have this issue.

A simple way to solve this stringing issue is to cut the extruded filament from the material in the nozzle by performing a wiping movement with the nozzle before moving the nozzle to another location.

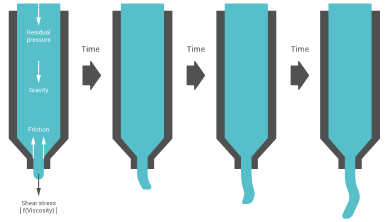

The second root cause is the actual material oozing created by the residual pressure and gravity which will force the material out of the nozzle over time.

As mentioned, the above 3 factors will define the amount of material oozing out of the nozzle:

Residual pressure, gravity and time.

In order to reduce oozing, we will need to decrease or counter each of them:

Residual pressure:

Residual pressure is a result of the printer building up pressure within the nozzle to extrude at a certain volumetric speed. This pressure can never be completely discharged from the nozzle over a very short period of time and therefore the material will keep extruding slightly. To decrease the residual pressure, we can increase the retraction settings (distance, speed), increase coasting (using the residual pressure to finish the layer), decrease the extrusion rate (need less pressure to extrude) or increase the printing temperature (need less pressure to extrude).

Gravity

Gravity will always pull the filament out of the nozzle, and if the gravitational force is stronger than the flow resistance of the plastic against the nozzle’s internal surface and shear within the plastic, it will ooze out. Note that the flow resistance between the internal surface of the nozzle and the plastic can be increased by increasing the die L/D ratio (L: length of the die capillary, D: diameter of the nozzle hole). The shear within the plastic can be increased by lowering the temperature of the nozzle (thus the stand-by temperature in several dual extrusion 3D printers).

Time

The amount of material oozing from the nozzle also depends on the amount of time the nozzle is inactive. The greater the duration, the larger amount of material there is. This time can be significantly reduced by having high travel speed, acceleration and reasonably high jerk settings. The material will not have time to ooze out before reaching the other part of the model. Having a high travel speed and acceleration should not affect ghosting as it would with increasing the print speed and acceleration. However, for dual extrusion printing, this factor cannot really be changed.

Last updated

Was this helpful?