Test Prints

These test prints are intended to test your ability to 3D print. It will go from easy to hard and will give Polymaker products as examples - though other similar materials may work well to test your printers capabilities.

For these tests we will not be using MakerWorld with their pre-sliced files. We want you to slice these files on your own so that you can learn more about the process.

The Material Science pages will help regardless of the print to understand how you can achieve a successful print.

It may be beneficial for you to start your own excel spreadsheet (or whatever method you prefer) to track your prints and how they came out. What could be improved and how you think they should be improved. This will be very beneficial to reference if you are not experienced with 3D printing.

Basic PLA Benchy in PolyLite PLA or Any Other Basic PLA

Difficulty: EASY Link to STL/Design File: https://www.thingiverse.com/thing:763622

Goal: Clean print with no flaws. This is the famous Benchy which is the go-to for the vast majority of makers to see how well their printer is running. You will see a lot of files on the download page but we are just going to be printing the standard Benchy uploaded 4/9/2015:

Tips:

Do you notice the license plate is hard to read? Ghosting and Ringing

Do you notice part of your print is shiny and part of it is more matte? Watch this Video.

Do you notice the top of the print is ugly even though the rest is fine? Ugly Tops

Is the hull line bulging? https://help.prusa3d.com/article/the-benchy-hull-line_124745

Oozing Test in PolyLite PLA or Any Other Basic PLA

Difficulty: EASY Link to STL/Design File: https://www.thingiverse.com/thing:909901

Goal: To understand why a part would get "stringy" or "hairy" and how to prevent it. This print is a very simple model but can be quite difficult to print clean if you do not know what you are doing. The printer will print a very small amount of material, stop extruding, travel to the next post, and continue the process over and over. If you do not do any tweaks to your settings, your print will likely turn out with a lot of string due to oozing. Bonus Test: Print in PolyLite PETG Difficulty: MEDIUM-HARD PETG is notoriously bad when it comes to oozing - so if you want a very difficult oozing test - reprint this model but use PolyLite PETG instead of PLA.

Tips:

Article on stringing and oozing.

More info on Material Science Article:

Warp Test in PolyLite ABS or Any Other Basic ABS

Difficulty: EASY - MEDIUM Link to STL/Design File: https://www.thingiverse.com/thing:1314956/files

Goal: Print without any warping or curling up of the bottom of your print. Printing in some materials including ABS and ASA can be difficult to achieve without any warping. This is particularly true if you are printing with a machine that is not enclosed. Enclosed printers make this process much simpler since they keep the ambient air hot, but printing this model without an enclosed printer is possible.

Tips:

Warping prevention tips.

Material Science to understand why this is happening.

Video printing ABS without an enclosure.

Video on Material Science.

Flexible Bracelet Test in PolyFlex TPU90 or Another Soft TPU

Difficulty: MEDIUM Link to STL/Design File: https://www.printables.com/model/217625-faceted-bracelet-bracelet-a-facettes

Goal: Understand the potential issues that can come from printing a soft TPU PolyFlex TPU90 is the softest material we offer. The "90" stands for "90A" - its shore hardness. The lower the shore hardness - the softer the material is. Soft materials can be difficult to print and sometimes even impossible if you are using a Bowden style extruder. You can use another TPU of any brand with a shore hardness of 90A or lower.

Tips:

Getting clogs? Try slowing your print speed down or increasing your extrusion temperature. A soft material such as this should be printed using as direct an extruder as possible - the larger the gap between your extruder and hotend, the slower you will have to print.

TPU is not the most hygroscopic material we offer but it is still susceptible to absorbing moisture. Check to see if you hear a "popping" or "cracking" noise when extruding to see if the filament needs drying.

Is your print really hairy/stringy? TPU is a particularly stringy material so it may be impossible to avoid this entirely. But you can take the tips from the "Oozing test" above to help mitigate this.

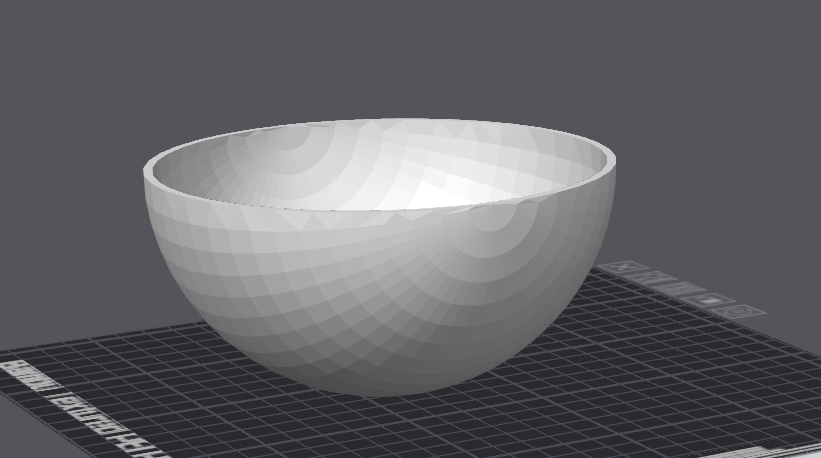

Overhangs/Supports Test in PolyLite PLA or Any Other Basic PLA

Difficulty: MEDIUM - HARD Link to STL/Design File: https://www.thingiverse.com/thing:2233996 Goal: Learn how to use supports and get clean overhangs by printing the bottom of a sphere

Before printing, make sure you orient the print in this manner:

This is not the best way to print this model - we are printing it in this orientation so that you can learn how overhangs work, since printing a sphere is extremely difficult in 3D printing.

The first few layers will have such an extreme angle that you will almost certainly need support structures. At some point in the sphere it will print cleanly without any supports.Your goal is to print as clean of an underside as possible.

This is not the best way to print this model - we are printing it in this orientation so that you can learn how overhangs work, since printing a sphere is extremely difficult in 3D printing.

The first few layers will have such an extreme angle that you will almost certainly need support structures. At some point in the sphere it will print cleanly without any supports.Your goal is to print as clean of an underside as possible.

Tips:

Article on printing a sphere.

Video on how to print without needing support material. You will likely need support material no matter what you try, but these tips can make it so the amount you need is reduced.

Older video on support settings. You may not be using Cura as your slicer but the tips in this video are still going to be valid for other slicers.

Overhangs in PolyMide™ CoPA or Another Standard Non-Composite Nylon

Difficulty: HARD Link to STL/Design File: https://www.thingiverse.com/thing:2151369 Goal: Understand the difficulties involved with printing CoPA, especially when it comes to overhangs

CoPA is a very difficult material to print, particularly for overhangs. This test is kind of designed to fail since you will certainly have issues, but you can learn more about the material as you try. If you are able to achieve a clean 55° angle - you are doing great. We normally suggest that a user avoids steep overhangs when printing in CoPA and design their part to not require supports, and you will likely find out why during this test. CoPA is very hygroscopic so make sure you keep the spool in a filament dryer the entire time you print. If you do not have a dryer - reach out to Nicolas Tokotuu to see if we can send you a PolyDryer.

Tips:

Video on how to print cleaner overhangs with settings tweaks.

Issues with warping or sticking to the build plate? Make sure your build plate temperature is set to correct temperature. Using some glue stick PVA will also help.

Hear "popping" or "cracking" when extruding? Your filament has absorbed moisture and definitely needs to dry. A wet spool of nylon will be near impossible to print cleanly

Play around with printing temperatures vs speed. CoPA is very temperature sensitive, increase or decrease your printing temperature by 5 degrees to see if you get a different result.

Score a 25-30 on Test Print in any PLA

Difficulty: HARD Link to STL/Design File: https://www.thingiverse.com/thing:2151369 Goal: This model is great to figure out random issues in a print - covering a gamut of potential problems.

Tips:

Reference the scoring system HERE to see tips and what your score is

Slowing print speeds and accelerations can help a lot with random errors and print quality issues

Scoring a 25 will be very difficult - so do not feel discouraged if you do not hit it. Printers can be very finicky with precision - such as with tolerances - so it may not be possible for you to hit a 25 if you do not have a well made printer.

Learn about input shaping and pressure advance if you are getting a lot of ghosting (ringing) and your corners are not sharp. Some printers like Bambu calibrate these automatically - others do not. As mentioned - reducing speeds and accelerations can help if you do not have these calibrations - but your print will take a lot longer to complete.

Last updated

Was this helpful?